Long recognized for the design and construction of sheet metal blanking dies, in recent years, Gima S.p.A. has expanded its network of collaborations in new and diverse sectors, all with a high level of innovation, performance, and know-how.

One of these is undoubtedly the field of high-end automotive electronics which, through one of its leading companies, commissioned Gima S.p.A. to design and manufacture four molds for the production of shaped ribbon-type flexible cables.

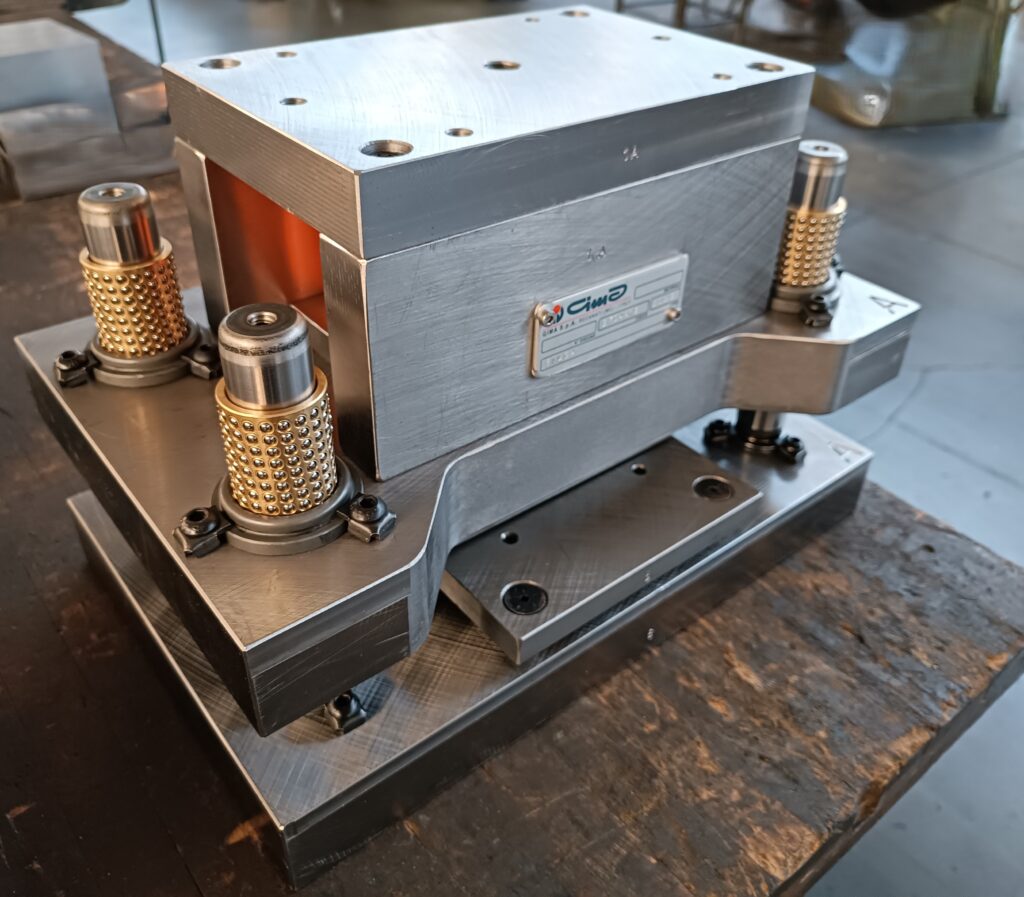

The need to achieve precise cuts with complex geometries, without damaging the thin and delicate cable material, required the design of highly accurate molds with top-quality components, capable of ensuring optimal results in full compliance with the applicable standards.

Particular attention was also devoted to the ergonomic aspects related to the use of these molds. This type of production, in fact, involves close interaction between the operator and the mold, which—combined with the small size of the cut parts and their manual collection—could have led to certain (albeit non-critical) issues concerning comfort and safety of use.

To address these aspects, specific technical solutions were implemented. Targeted component positioning, the use of tailored working heights, and, not least, the incorporation of curved geometries (implemented in one of the upper plates) create a recess designed to extend the operator’s field of view inside the mold.

A project with exceptionally high technical and quality standards, broadening the horizons of our design and manufacturing capabilities and highlighting the company’s flexibility in innovating through new technologies and expertise to meet the demands of a rapidly evolving market.

The success of this project is concrete proof that Gima S.p.A. is not only able to meet traditional needs in the field of blanking, but is also ready to seize the opportunities offered by technological innovation and to adapt to new industrial contexts with a flexible, dedicated, and forward-looking approach.