In today’s global market, our industry faces numerous daily challenges. Complex geometric parts, small metal parts turned with milling, broaching, slotting, threading, cross-boring, rolling, and other processes that, until recently, were impossible to finish on a single lathe.

This is no longer the case, and requests for these types of parts arrive on our desks daily. For this reason, it is essential to have a technologically advanced, flexible, and varied fleet of machines that allows us to reduce times, setups, waste, rework, and therefore costs, so as to be competitive in emerging markets.

At Gima S.p.A., we have always focused on the sliding headstock lathe, our flagship model. We believe it is the machine that best embodies our corporate vision. In our ongoing search for equipment that can support us in our daily technological challenges, we have identified and purchased a new model to enhance our workshop.

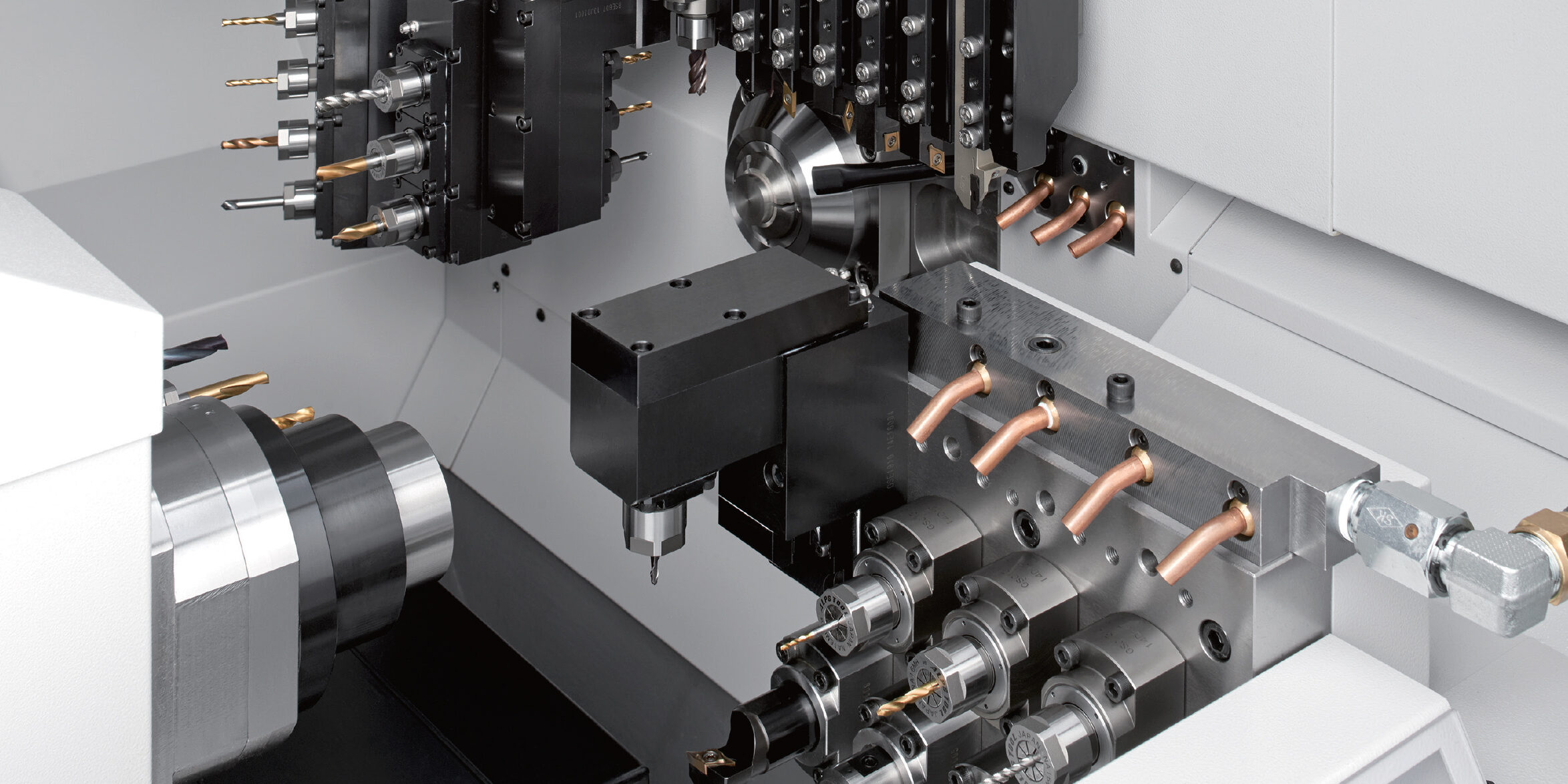

Thanks to a close collaboration with Citizen Italia, in addition to the two Citizen Cincom L220 lathes already purchased in March, we are now installing the Citizen Cincom L32-XII, which has become our flagship sliding headstock lathe for large parts. With its 9 CNC axes, it represents the ultimate in versatility and reliability. Thanks to LFV (Low Frequency Vibration) technology, it can machine materials with poor chip removal rates with excellent results, reducing the size of the chips and thus facilitating machinability. So, what does chip removal mean? It is the ability of a material to be machined on machine tools by removing chips. Over the past few years, Gima has specialized in machining materials with low machinability. Through in-depth studies on the selection of cutting tools, lubricants, and suitable equipment, we are able to offer a competitive turning service for all those “challenging” products, such as stainless steels (AISI 304L, AISI 316L) and weldable steels like S235JR.

The L32-XII machine, works with and without a compass to reach a diameter of Ø38 mm, thus covering a wide range of our products in production and offering a very competitive alternative in terms of cycle time, compared to the other machine tools present in our workshop.

The L32-XII machine, works with and without a compass to reach a diameter of Ø38 mm, thus covering a wide range of our products in production and offering a very competitive alternative in terms of cycle time, compared to the other machine tools present in our workshop.

This investment also aims to reduce our environmental impact; for years, Gima has implemented an integrated Environment-Safety-Quality management system. Thanks to the purchase of this cutting-edge lathe, we aim to reduce our energy consumption by replacing obsolete, energy-intensive machines. For this reason, we have joined the Transition Plan 5.0 (Industry 5.0) and are proud to be able to contribute.

The machine operators are more than satisfied with the new acquisition, always motivated by challenges and ready to continue their training to master different programming languages and numerical controls. From this perspective, the role of the CNC lathe operator/programmer needs to be reevaluated. This dynamic, well-prepared professional supports the company in various areas, from setup to quality, including environmental, safety, and logistics. This role is completely integrated with the company and increasingly represents our flexibility.

Stay tuned for more news, it will be a year full of opportunities!