Metal turning, stamping and sheet metal forming: news and updates from the world of Gima S.p.A.

In January 2026, Gima S.p.A. delivered a new automation dedicated to the world of fashion accessories and religious items. The machine in question, fully automated, creates and assembles chain links directly onto the pendant, which can differ in shape and size. This is precisely its peculiarity: the machine is a direct evolution of the four…

Details

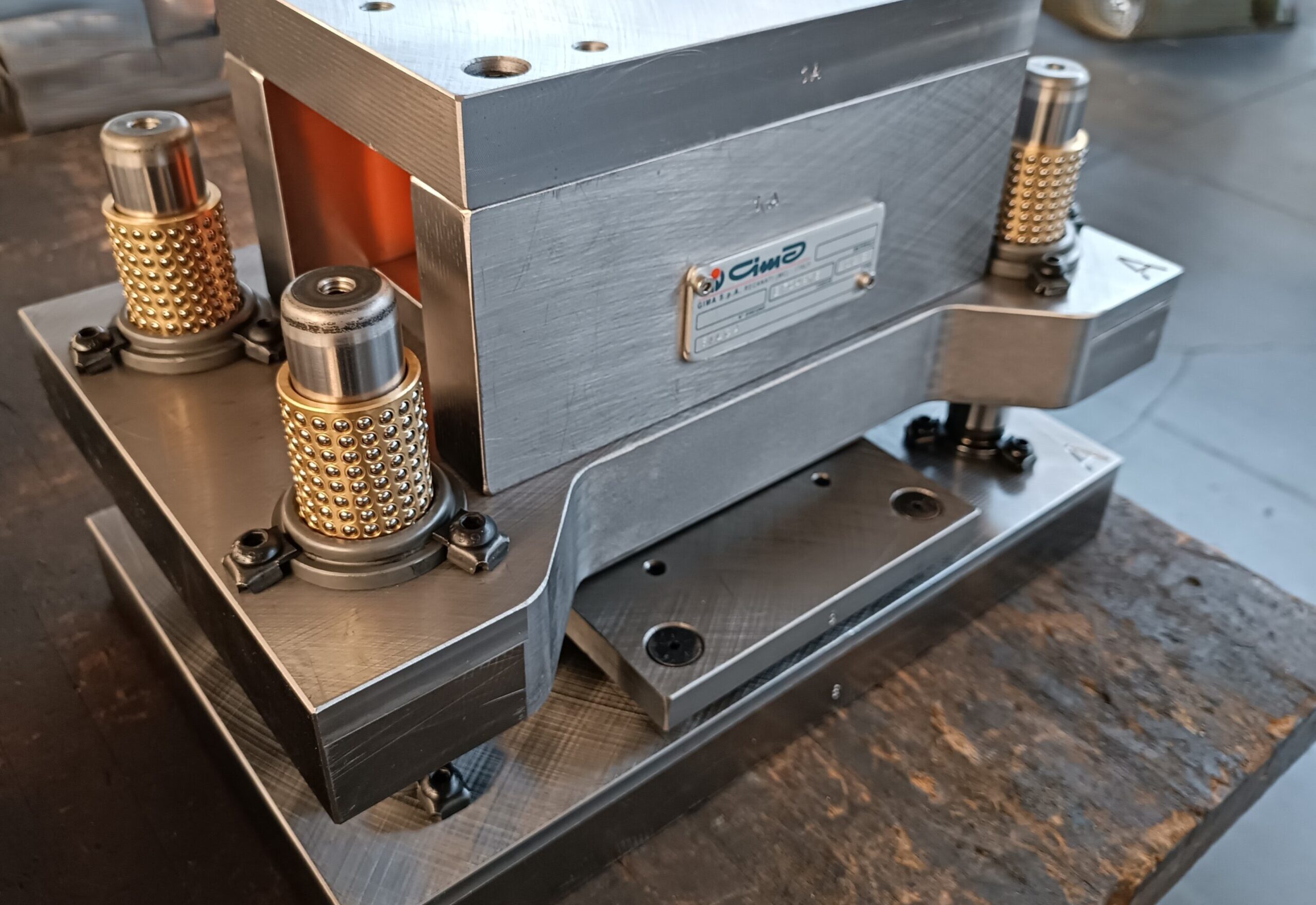

Long recognized for the design and construction of sheet metal blanking dies, in recent years, Gima S.p.A. has expanded its network of collaborations in new and diverse sectors, all with a high level of innovation, performance, and know-how. One of these is undoubtedly the field of high-end automotive electronics which, through one of its leading…

Details

On Friday, September 19, 2025, the new Small Industry Committee of Confindustria Macerata was presented in the beautiful municipal theater of Treia. It was an opportunity for entrepreneurs, the local community, and institutions to discuss a highly topical issue that is increasingly becoming part of everyday life for people, and even more so for businesses.…

Details

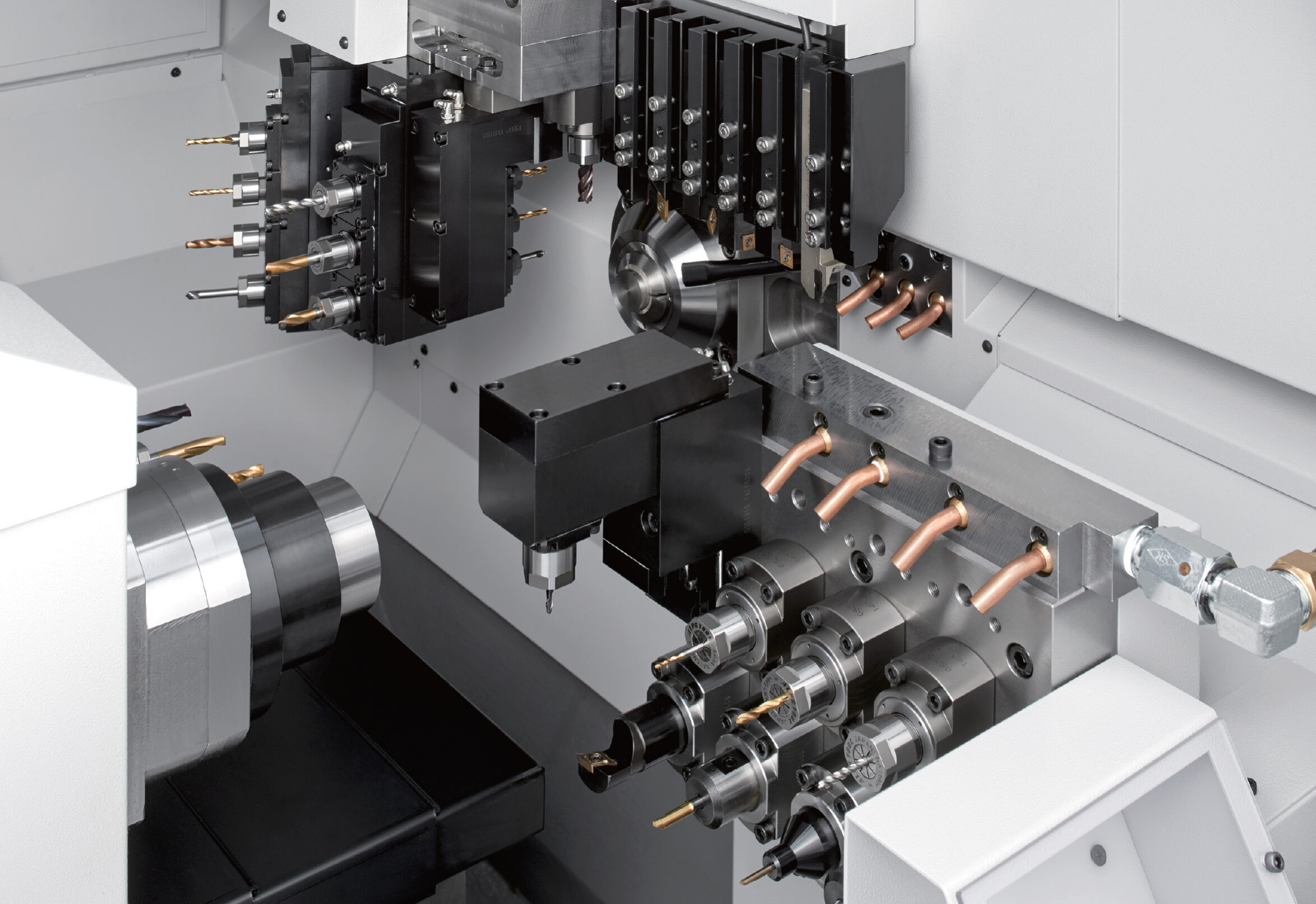

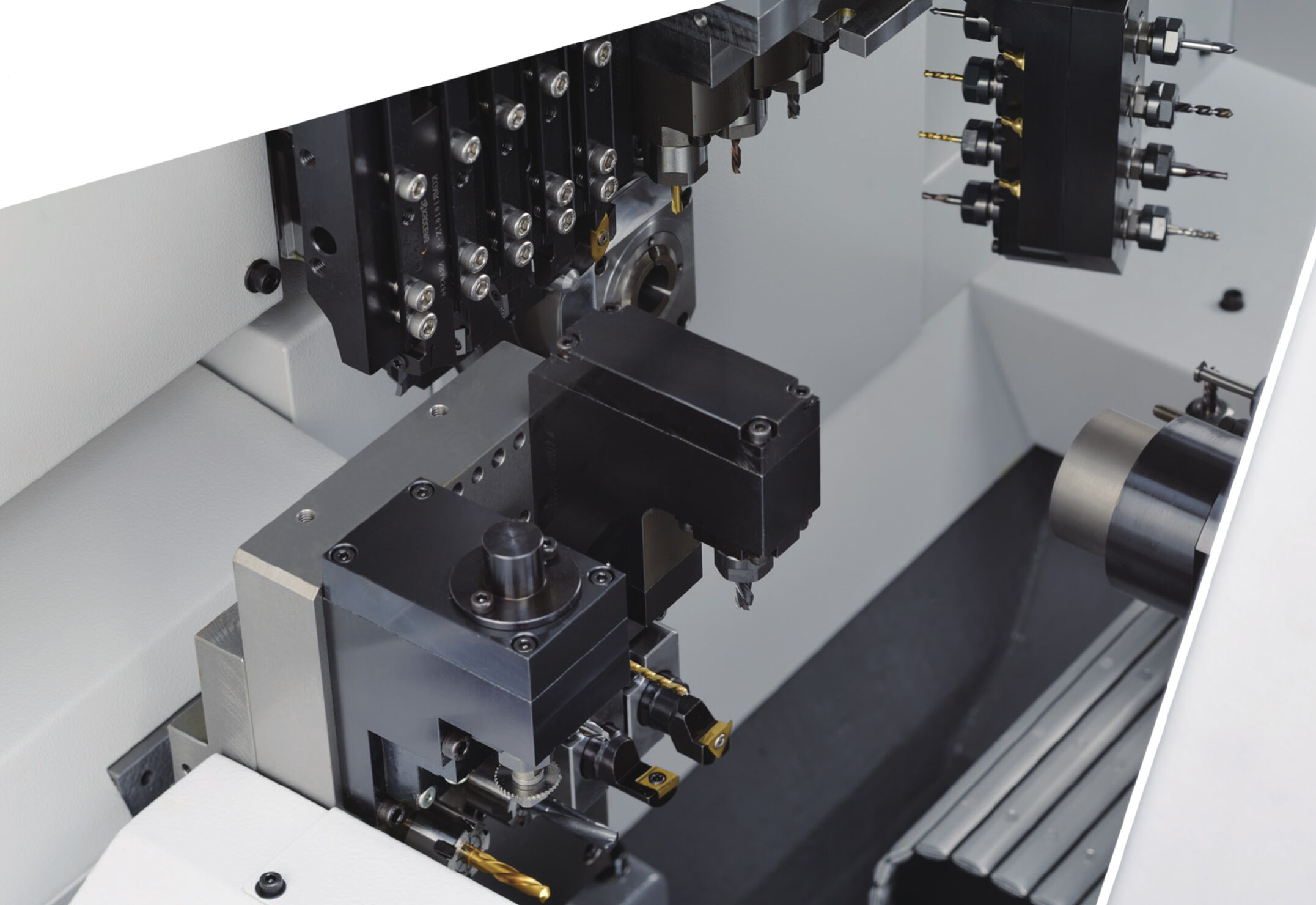

In today’s global market, our industry faces numerous daily challenges. Complex geometric parts, small metal parts turned with milling, broaching, slotting, threading, cross-boring, rolling, and other processes that, until recently, were impossible to finish on a single lathe. This is no longer the case, and requests for these types of parts arrive on our desks…

Details

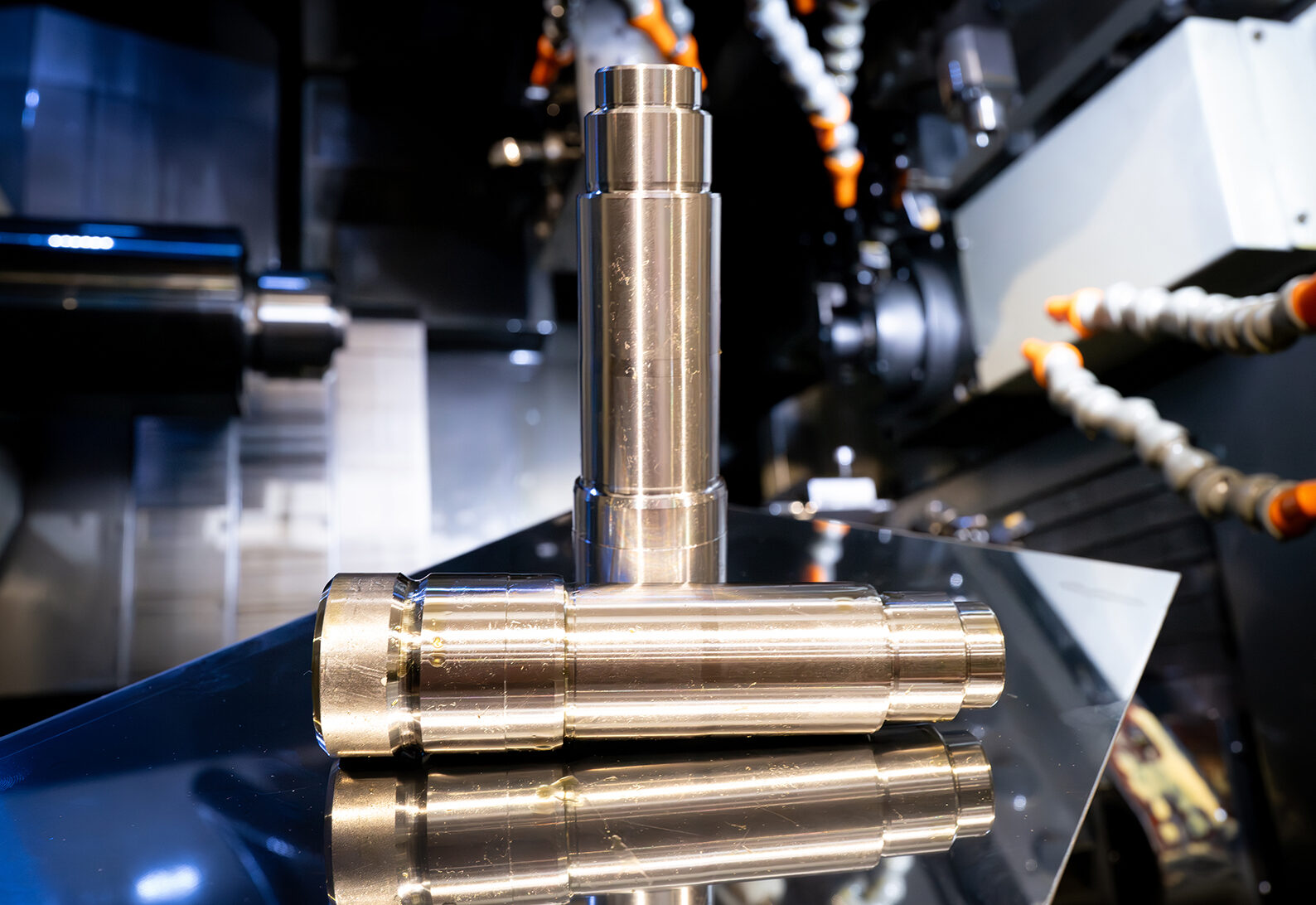

In a constant effort to test its skills and know-how in sectors characterized by innovation and high technical and technological standards, Gima S.p.A. has, in recent years, established close collaborations with some of the most renowned national manufacturers and suppliers in the automotive and general transport industry. Thanks to its ability to meet customer production…

Details

Following the collaborative relationship established over the years and the recent training sessions conducted by our technical staff, on Friday, May 23, 2025, Gima SpA was invited to take part in the career orientation day organized by the Istituto di Istruzione Superiore “Enrico Mattei” in Recanati, dedicated to senior-year students. We responded to the invitation…

Details

Our Past: Located geographically in an area that, since the onset of industrialization, has shown a strong vocation for the white goods sector—and washing machines in particular—Gima S.p.A., headquartered in the Marche region, has been operating for over 30 years as a strategic supplier to the world’s largest multinationals in the industry, exporting its products…

Details

In April 2025, Gima S.p.A. completed the fabrication and delivery of a batch of 3 semi-automatic machines on behalf of a third party (to complement a fully automatic machine previously delivered), designed for the construction and assembly of rings for pendants, intended for use in fashion accessories and religious items. Machine features The machine, custom-built…

Details

Together for a sustainable future An integrated system for Quality, Environment and Safety considered as a real department, three certifications for infinite strengths that fully represent the company’s organisational approach. We are pleased to announce that in March, Gima S.p.A. successfully obtained the UNI EN ISO 45001:2018 certification for Occupational Health and Safety and the…

Details

The future of automatic turning In the automatic turning industry, in an increasingly fast-paced, demanding and globalised world, staying abreast of new technologies and ensuring the production of turned small metal parts at high volumes, low costs and within fast turnaround times is a primary requirement of all leading companies in the sector. Reducing turning…

Details