Con il termine tranciatura la Gima spa intende l’intero reparto dedicato allo stampaggio a freddo delle lamiere. Durante il corso degli anni, le lavorazioni delle lamiere hanno assunto sempre maggiore importanza nell’industria metalmeccanica grazie all’elevato numero di manufatti realizzabili con tali procedimenti: dalle carrozzerie delle automobili al settore elettrodomestico, dai mobili agli organi per la meccanica fine, ecc.

La tranciatura delle lamiere è una lavorazione meccanica che si effettua quasi sempre a freddo e risulta particolarmente adatta a grandi quantitativi di produzione, dato il suo basso tempo ciclo e di conseguenza il suo costo ridotto.

Fra le minuterie metalliche producibili da Gima spa all’interno del proprio reparto di tranciatura metalli ci sono: cerniere in lamiera, particolari per serrature e per elettrodomestici, chiavi, accessori per strumenti musicali, molle, bussole imbutite, fibbie, oggetti in acciaio inox, in ottone, in alluminio e in acciaio armonico, ecc.

In particolare, all’interno del reparto tranciatura Gima Spa si eseguono le lavorazioni meccaniche elencate di seguito:

Come funziona la tranciatura

La tranciatura è generalmente la prima operazione nel ciclo produttivo delle lamiere; con essa si realizzano sia semilavorati di partenza che prodotti finiti, ed è votata ad ottenere sezioni piane prefissate.

La tranciatura è generalmente la prima operazione nel ciclo produttivo delle lamiere; con essa si realizzano sia semilavorati di partenza che prodotti finiti, ed è votata ad ottenere sezioni piane prefissate.

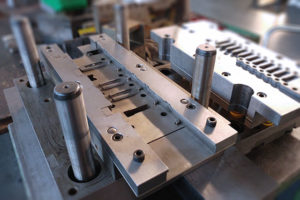

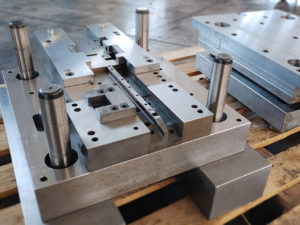

L’operazione di tranciatura viene effettuata sotto pressa mediante l’ausilio di uno stampo composto da due utensili, chiamati “punzone” e “matrice”, e consiste nel sollecitare un laminato piatto fra questi due taglienti, fino a generare una frattura che riproduce proprio la forma dei taglienti stessi.

In pratica il punzone penetra nella lamiera, la attraversa entrando all’interno della matrice e ne asporta un profilo predefinito. Un parametro molto importante nella suddetta operazione è il “gioco” – anche detto “luce” – esistente fra punzone e matrice.

Un’importante componente per ottenere materiali tranciati di elevata qualità, oltre alla realizzazione di un buono stampo di cui parleremo nella sezione Costruzione Stampi e Progettazione, riguarda la scelta della pressa.

Le presse possono essere suddivise in presse idrauliche e presse meccaniche. Le prime sono azionate da un fluido idraulico agente su uno o più pistoni e risultano particolarmente adatte per le imbutiture profonde ma sono caratterizzate dalla bassa velocità.

Le presse meccaniche possono a loro volta essere suddivise in presse ad eccentrico e presse a ginocchiera. Data la loro maggiore velocità, esse si prestano meglio a lavorazioni di tranciatura, (che richiedono un forte colpo dell’utensile contro la lamiera) e, svolgendo il ciclo più rapidamente, sono adatte a ritmi di produzione più elevati. Il loro moto è ottenuto sfruttando un volano posto in rotazione da un motore elettrico. Il volano viene a sua volta collegato a un eccentrico, nel caso delle presse a eccentrico, e a una ginocchiera, nel caso di presse a ginocchiera.

La tranciatura metalli e lamiere Gima

La Gima spa, forte di un’esperienza nelle operazioni di tranciatura maturata sin dalla sua nascita, e grazie anche ai continui investimenti operati per l’acquisto di nuove attrezzature, può vantare un parco macchine invidiabile, dotato di 25 presse meccaniche, sia ad eccentrico che a ginocchiera, con una forza massima fino a 315 tonnellate e piani di lavoro di lunghezza superiore ai due metri.

Il tutto situato in uno stabilimento di 5500 mq, in cui risiede anche un’officina specializzata per la costruzione e la manutenzione degli stampi, al fine di ottenere velocità e flessibilità di produzione, annullando quasi completamente i fermi macchina dovuti a rotture o usure, e offrendo al cliente un prodotto di qualità con un basso lead time.

Imbutitura

L’imbutitura è un processo tecnologico che permette di ottenere un corpo cavo, di forma scatolare, cilindrica o a coppa tramite una profonda deformazione plastica. In sostanza, il termine imbutitura indica la lavorazione meccanica con cui si ottengono particolari come lattine, pentole e altri contenitori prodotti in un unico pezzo, a partire da una superficie piana di metallo laminato (lamiera).

L’imbutitura è un processo tecnologico che permette di ottenere un corpo cavo, di forma scatolare, cilindrica o a coppa tramite una profonda deformazione plastica. In sostanza, il termine imbutitura indica la lavorazione meccanica con cui si ottengono particolari come lattine, pentole e altri contenitori prodotti in un unico pezzo, a partire da una superficie piana di metallo laminato (lamiera).

La lamiera costituisce il materiale di partenza, e viene serrata fra la matrice e un premilamiera. Quest’ultimo limita la formazione di grinze, facendo confluire in modo progressivo e a velocità controllata il materiale all’interno della matrice, una volta che il punzone entra in contatto con il pezzo, deformandolo.

La Gima spa è dotata di stampi transfer ideali per l’imbutitura profonda, e da oltre trent’anni realizza per i formifici di tutto il mondo bussole di lamiera con un rapporto fra lunghezza e diametro sino a 4,5 volte.

Piegatura

Un’altra lavorazione meccanica di routine all’interno del reparto di tranciatura metalli e lamiere è la piegatura. Molto spesso essa è considerata un processo in combinazione con altre operazioni, quali imbutitura e coniatura, per definire più generali e complesse operazioni di formatura dei metalli.

L’operazione di piegatura consiste nella formazione di pieghe su di una lamiera piana al fine di ottenere geometrie complesse che si sviluppano nelle tre dimensioni.

Coniatura

Il processo di coniatura consiste nell’obbligare un semilavorato di partenza ad occupare un determinato profilo cavo ottenuto fra punzone e matrice, deformandolo. È la lavorazione meccanica con cui vengono realizzate le monete e le medagliette, con la possibilità di riportare in superficie disegni o scritte. Mediante una pressa e la sua ingente forza, si costringe il materiale a fluire nelle intercapedini, al fine di ottenere il profilo richiesto.

In alcuni casi, il processo di coniatura può essere utile per eliminare le bave di tranciatura o per migliorare la planarità del pezzo.

Gima spa è in grado di ottenere qualsiasi particolare metallico richiedente operazioni di coniatura.

Gima spa dispone inoltre, nel proprio reparto di tranciatura, di macchine piegafilo, utilizzate per la realizzazione di molle impiegate nella costruzione di forme per calzature. Tale filo è generalmente in acciaio armonico temprato. Contattaci per richiedere qualsiasi informazione.