An effective control of mechanical forces guarantees a longer life of the cutting tool.

Milling is a machining operation which allows to craft a workpiece through material removal. Unlike turning, where the resulting parts are axial-symmetrical, the cutting tool, called mill, is set with a rotational movement around its axis, while the workpiece moves along the 3 axis.

Moreover, in turning, the cutting tool is a single cuneiform cut-off tool, while, in milling, the tool has multiple cutting edges, which interacts one-by-one to remove chips, returning the requested shape of the workpiece.

We advise to adopt several precautions in order to obtain good quality machined surfaces and to avoid eccessive wearing of the cutting tools.

Up milling vs down milling: how to choose?

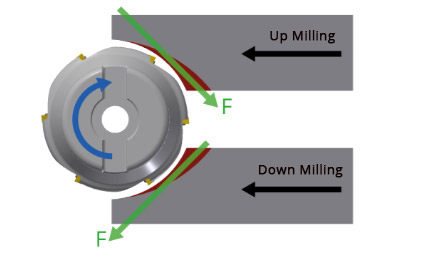

In down milling, the rotation of the cutting tool has the same direction of the workpiece feed; in up milling, instead, the directions are opposite. For wearing protection, the down milling is almost always preferred because of different reasons:

- in up milling there is a bigger friction of the cutting the tool, which results in a higer wear;

- the down milling favors heat trasfer to the chip, protecting both the workpiece and the tool;

- with down milling it is harder for the chips to remain trapped between the tool and the workpiece, since they are throwed away behind the milling cutter by its rotary movement.

Only in few case the up milling could be desiderable. In example, in heavy load operations or with old and unstable machines, since down milling generates downward forces that could lead to unwanted movements of the workpiece.

Only in few case the up milling could be desiderable. In example, in heavy load operations or with old and unstable machines, since down milling generates downward forces that could lead to unwanted movements of the workpiece.

Moreover, with down milling, the tool begins the cutting of the chip on its maximum thickness. This means that the tool is subjected to high mechanical loads and it is important to ensure that the tool is suitable to withstand this strain. The current inserts and mills are made of cemented carbide, HSS steels or ceramic obtained by synthesization, which ensure high resistance to compression forces.

When to apply cutting fluid?

In this case we must differentiate between roughing and finishing operations. During roughing, the cutting edges are subjected to thermal shocks due to temperature variations, causing thermal cracks. The general rule is to execute roughing via dry milling, while finishing, could be executed using fluid. During finishing, in fact, the thermal variations are more limited.

The cutting fluid can be used on stainless steel or aluminium components, on heat resistant alloys or cast iron, and it is useful to remove dust and to cool down the part.

Control vibrations

The stability of the milling operation is essential for a long life of the cutting tool. For this reason it is very important to limit vibrations:

The tangential milling cutter is a more rigid tool, useful for vibration reduction.

- the holding tool must be the largest as possible and the complete tool assembly should be the most short and rigid as possible. For small milling cutters, use a tapered adaptor.

- the tool path: use a small depth of cut and a high feed speed in face milling, with round or 45° inserts. Program a large corner radius to avoid vibrations on inner angles and increase feed if the chip thickness becomes too low.

- the workpiece fixture and the machine: it is important to ensure a rigid locking of the workpiece on the table and check the good working conditions of the machine to contain vibrations.

Entering and exiting the compontent

The life of the milling cutter depends, in large way, by how the entrance is programmed, specially for steel or hard materials. A gradual approach is always preferable over a direct approach, and it is very important to choose the most appropriate strategy, depending on the specific operation.

The life of the milling cutter depends, in large way, by how the entrance is programmed, specially for steel or hard materials. A gradual approach is always preferable over a direct approach, and it is very important to choose the most appropriate strategy, depending on the specific operation.

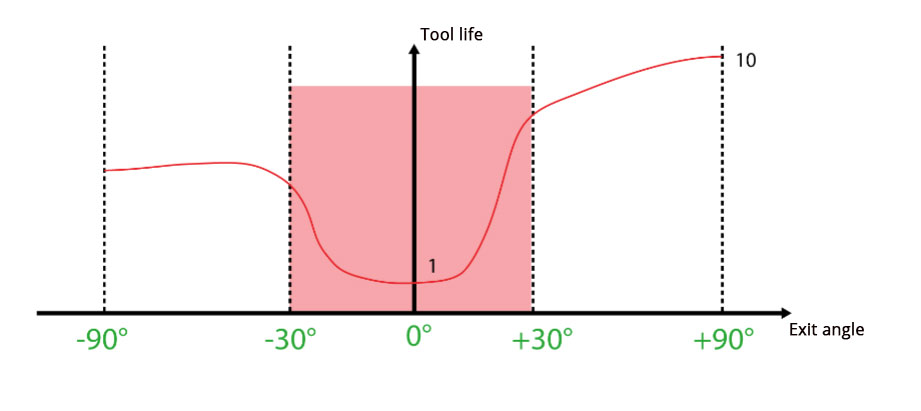

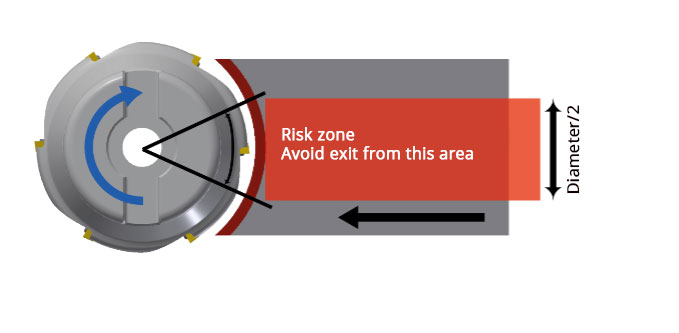

The avoid early wear, the exit from the component is important as the entrance: if the exit is not uniform, there could happen breakage or edge chipping.

To avoid this, it is required to carefully program the “exit angle”, that is the angle between the tool radius and the exit point from the workpiece. An exit angle greater or lesser than +/- 30° maintains the cutting edge intact for a longer time.

Chip thickness

Another essential aspect for an effective milling is the maximum chip thickness obtainable by a cutting edge. It is important to not overload the cutting edges with too thick chips, but, at the same time, the thickness should be not too low to avoid loss of productivity/efficiency.

The best value for chip thickness is specified by the producers, and it is the arithmetic mean between the minimun and maximum design values.

Gima Spa’s milling

Gima Spa is a modern company for turning and milling operations. For this kind of machining, Gima Spa features ten transfer milling machines, five up to to 4-axis CNC centres, for a production service of metal parts suitable for every need.

***

Thanks to Macchine Utensili News for informations included in this article.