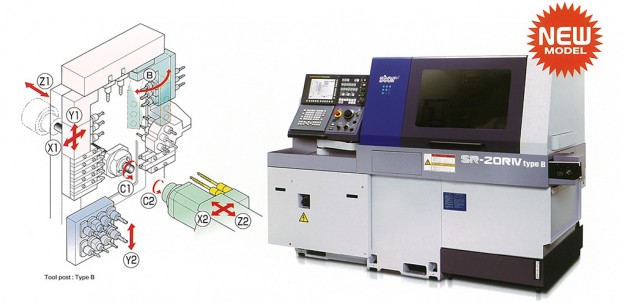

Thirty years of Gima Spa: since 1986 fine metalworking for every need.

Constant innovation, high quality metalworking and a clear vision of the company aims are the keys that lead Gima Spa to celebrate its 30th birthday on 5 June 2016. This 30 years route encloses what this company rapresents: trust in people, constant modernizations of machinery and, with the course of time, expansion to international markets.…